”@”@Mr. Guo pointed out that as a small-scale company, Tenny’s success resulted from the efforts of the whole team.

”@”@The Team

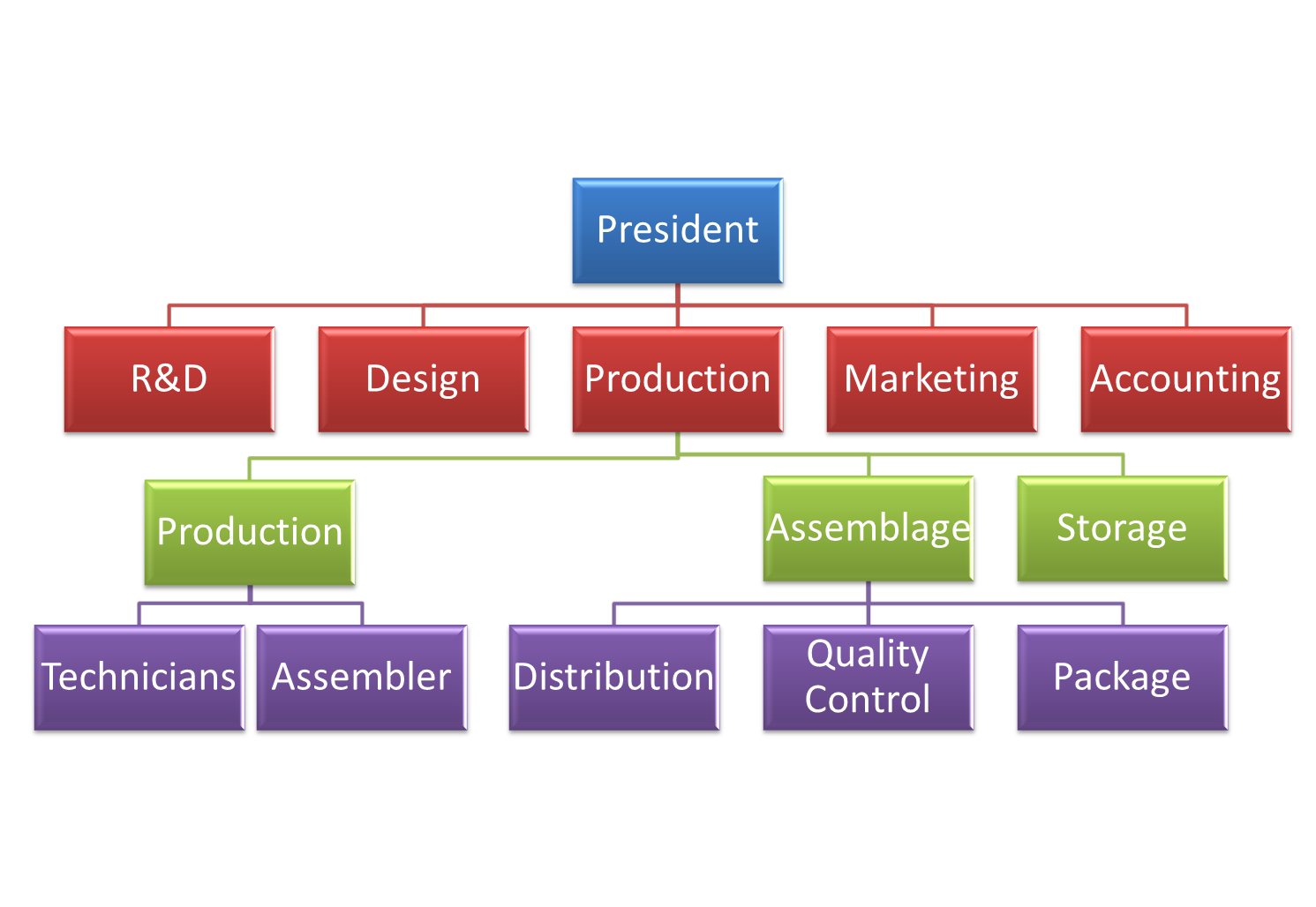

”@”@ In order to facilitate the operation, Tenny Co. set up several departments. ( Figure 1-3-1) They put the same work in one department, and the president is in charge of every thing to make sure the company is running in high efficiency.

|

| Picture 1-3-1: Tenny’s Organization Chart |

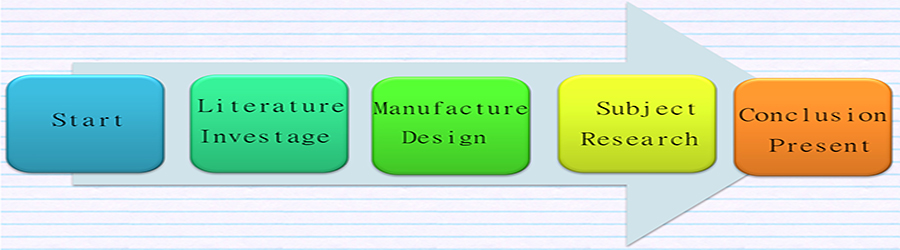

”@”@Manufacturing

”@”@There are 2 procedured for producing pens: deal with pen loops, grips assembling, pen base parts grinding in the factory, and then assemble them.

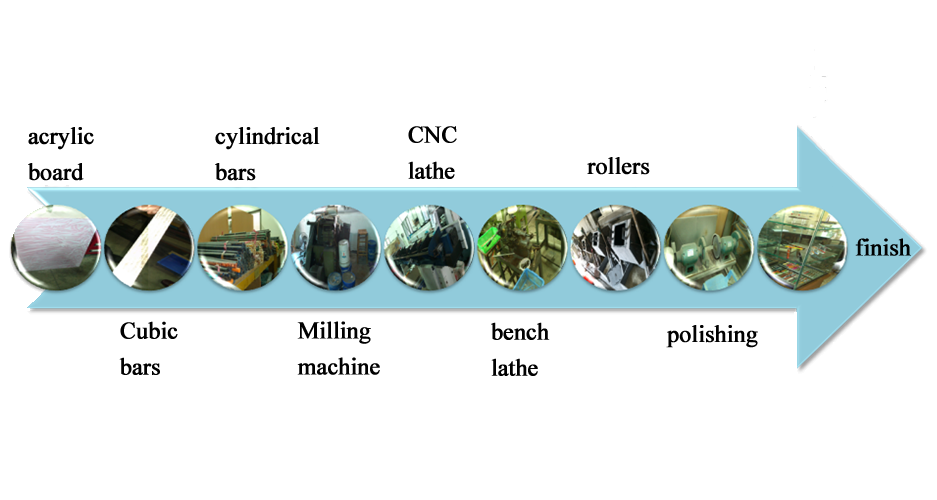

Procedure 1: pen base parts grinding

”@”@The technicians with 20-year experience lead to manufacture, cutting, grinding and polishing with a lathe.

|

| Picture 1-3-2: Procedures for TENNY’s pen manufacturing |

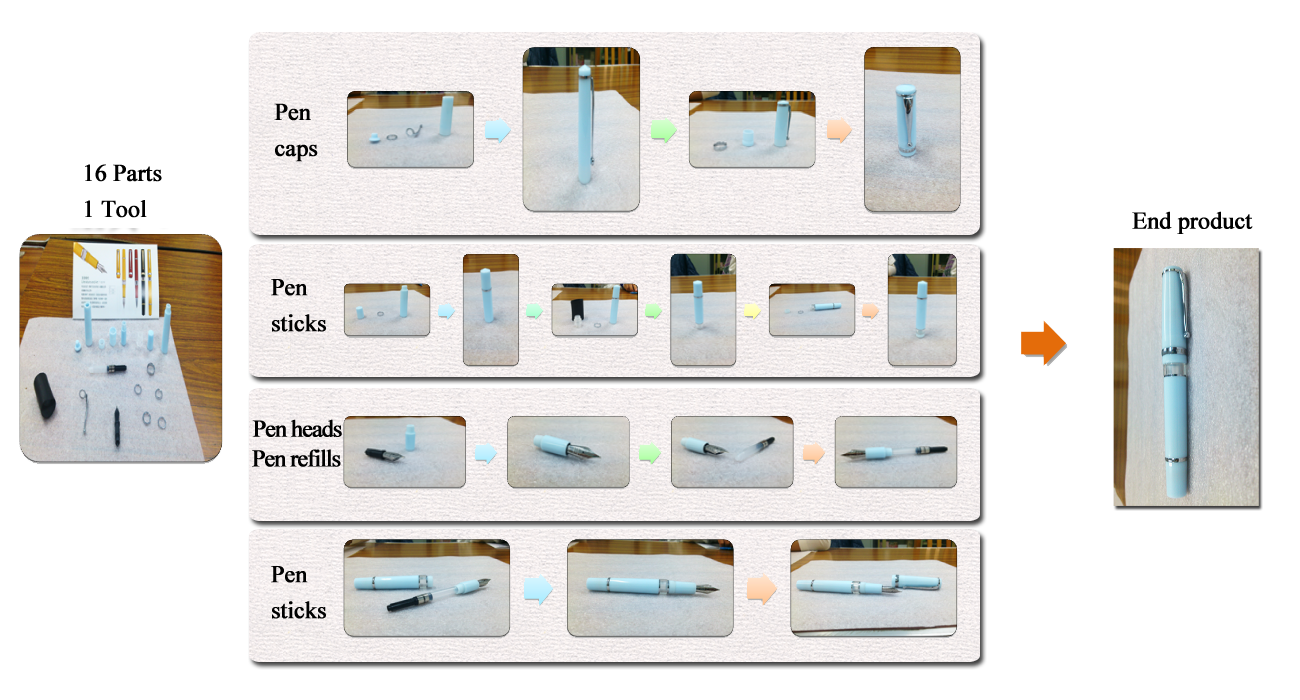

Procedure 2: Pen parts assembling

”@”@It is the last step to assemble the parts, which are semi-finished components, pen cores and West Germany original nibs.

|

| Picture 1-3-3: TENNY’s pen assembling and structures |